Air entraining agents are used by themselves or teamed-up with other concrete additives to enhance concrete properties. Far from being an extra cost, air entraining agents have established themselves in the concrete industry with serious players as a must-have to:

- Improve workability,

- Reduce bleeding, and

- Increase the freeze thaw resistance of concrete.

There are several valid arguments to incorporate an air entraining agent in the concrete mix design. For the purpose of this post, only the top 3 reasons will be explained in detail.

But first, some terminology.

What is Air Entrainment in Cementitious Mixes?

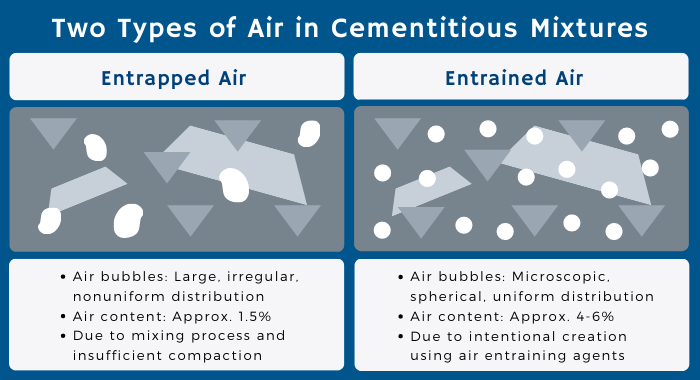

Air entrainment is created by design. This process consists of producing air bubbles within the concrete mix though mechanical agitation. But these are not common air bubbles that are irregular and visible to the naked eye. Air entrained bubbles are microscopic, innumerous, and spherical. Also, they have an evenly spaced distribution. Entrained air bubbles usually maintain a distance of 0.25 mm between each other. In addition, 4% to 6% of these well-distributed air bubbles can be incorporated into cementitious mixtures.

Below is an infographic comparing the types of air found in cementitious mixes.

Improve Workability of Concrete with an Air Entraining Agent

One way to increase the workability of cementitious mixes is by simply adding more water. By increasing the water to cement ratio, the mixture becomes more fluid. But that decision comes with its own set of problems – like the bleeding of concrete. So, it’s time to improve workability with better methods.

With air entrainment enabled, the air bubbles within the mixture act as a lubricant within the concrete mix. Thus, increasing the fluidity. The enhanced workability enables the mixture to be pumped and transported to its intended location within the construction site with better efficiency.

A pro tip is to include an air entraining agent in the concrete mix design especially when using artificial sand. Differently from natural sand, artificial sand is less spherical and irregularly shaped. Applying the same principle as explained before, the entrained bubbles enhance fluidity of a concrete mixture with artificial sand.

An Air-Entraining Agent can Decrease Bleeding of Water in Concrete

In short, bleeding occurs when water rises to the surface of freshly poured concrete.

Essentially, concrete is composed of four materials: cement, sand, stone and water. Water is the only liquid and the least dense of these four ingredients. Thus, water that was not absorbed into cement or sand tends to rise above the denser materials of the mixture. The result is a puddle of water that “bled” to the surface of freshly poured concrete.

Enabled by air-entraining agents, air bubbles increase the surface area water and cement need to cover. The outcome is a more balanced mixture, which has less water rising to the surface of freshly placed concrete.

Increase Freeze Thaw Resistance by adding an Air Entraining Agent to the Concrete Mix Design

Water can do amazing things for concrete, but it can also cause damage. Concrete that was not properly prepared for climate variations can suffer from the extreme heat and cold. In regions where negative temperatures occur, concrete needs to be able to resist the freeze thaw cycle.

The main reason air-entraining agents are added to concrete mix design is to increase its freeze thaw resistance. The air bubbles created through air entrainment act as “expansion chambers” for water. Why does water need space to expand? Because frozen water occupies 9% more volume than water at room temperature. If air entrainment did not happen, frozen water will make space for itself by creating minuscule cracks within concrete. Over time, this repeated cycle of freezing and melting of water causes micro fractures to become large-scale problems. Thus, by simply adding air-entraining agents to the concrete mix design, the resistance to freeze thaw can be greatly increased.

Did you enjoy this blog post?

Let us know by sharing it via LinkedIn or comment on our LinkedIn Page.

Looking for air entraining agent examples? Look no further.

Published on 01-APR-21.