Cationic emulsions are widely adopted and used around the world in road surface binder technologies and asphalt products. But that was not always the case. The Anionic Stable Grade Bitumen Emulsion, also known as the SS60, is a versatile and forgiving product. Compared to its cationic countertype, the CSS60, the SS60 has several advantages. The 5 top-of-mind reasons to select anionic bitumen emulsions instead of cationic emulsions for slow set applications are:

- Cationic emulsions are corrosive,

- Anionic emulsions are safer,

- User-friendly,

- Storage stable, and

- Eco-friendly.

1) Cationic Emulsions are Corrosive

The anionic SS60 has an alkaline pH typically between 11 and 12. On the other hand, the cationic CSS can have a pH as low as 1. In other words, CSS is highly acidic. With an acidic pH, cationic emulsions have a tendency of devouring mild steel parts of emulsion mills, pumps, and tanks. Another victim of the corrosive pH is its steel drum packaging.

2) Anionic Emulsions are Safer

With CSS being highly acidic, it is also not as user friendly and safe as anionic emulsions. Of course, in both cases it is advisable to use the appropriate personal protective equipment (PPE). However, the low pH of cationic emulsions warrants additional care, whereas anionic bitumen emulsions have been proven to be safe for use in the waterproofing of fishponds. When it comes to protecting human workers and animal life, anionic emulsions are the better choice.

3) Anionic Bitumen Emulsions are User-Friendly

This type of emulsion is more suitable for handwork and labor enhanced construction practices. Anionic emulsions are an excellent example of user-friendly bituminous products that have a long track record of gainfully employing local laborers. There is a large focus on job creation and enabling women in the road construction industry. These men and women perform essential maintenance, construction of slurry seals and penetration McAdam construction techniques on their local road system.

4) Anionic Emulsions are Storage Stable

Because anionic bitumen emulsions have a long shelf-life, many engineers consider it more suited for transport into remote locations than their cationic countertype. This knowledge stems from years of practical experience. Also, the product has earned the reputation of best choice for use in rural and remote road construction. In such places, the surrounding infrastructure is often insufficient, such as appropriate storage conditions. Also, construction rates are slow. Thus, anionic emulsions are the most appropriate choice here.

5) Anionic Emulsions are Eco-friendly

Our planet is facing huge climatic and pollution challenges. Anionic bitumen emulsions are manufactured with emulsifiers originating from natural and renewable resources. The resin-based emulsifiers are responsibly harvested from oxygen producing trees. Thus, they promote the protection of trees with the eco-friendly production of emulsions.

The Uses of Anionic Emulsions in Slow Set Applications

In South Africa, the split between cationic and anionic emulsion differs considerably from what is observed elsewhere in the world. The hot and dry climate in South Africa is conducive for the use of anionic bitumen emulsions, especially in:

- Slurry seals,

- Cape Seals, and

- Bitumen emulsion treated bases (ETB).

On the other hand, rapid set spray grade emulsions mostly use the cationic countertype.

Slurry Seals

A well-known institution in South Africa, Sabita is the Southern African Bitumen Association. They have a plentitude of materials both on anionic and cationic emulsions, which anyone can use as a reliable resource.

In Sabita’s Manual 28, “The Best Practices for the Design and Construction of Slurry Seals” (June 2011) they educate how to create the best slurry seals from anionic emulsions.

Cape Seals

This chip-and-slurry-seal combo is described in another of Sabita’s guides, Manual 40/TRH3 “Design and Construction of Surface Treatments” (February 2021). The recently revised TRH3 is evidence of how anionic bitumen emulsion earned its stipes in the construction of one of the most durable sprayed seal types.

Bitumen Emulsion Treated Bases

In August 2020, Sabita released the updated version of the Technical Guideline 2, “A Guideline for the Design and Construction of Bitumen Emulsion and Foamed Bitumen Stabilized Materials,” fondly referred to as the TG2 Third Edition. The TG2 encapsulates the use of both anionic and cationic bitumen emulsions in detail. Also, it explains the reasons why anionic bitumen emulsions are still considered the preferential product for emulsion treated base (ETB) applications.

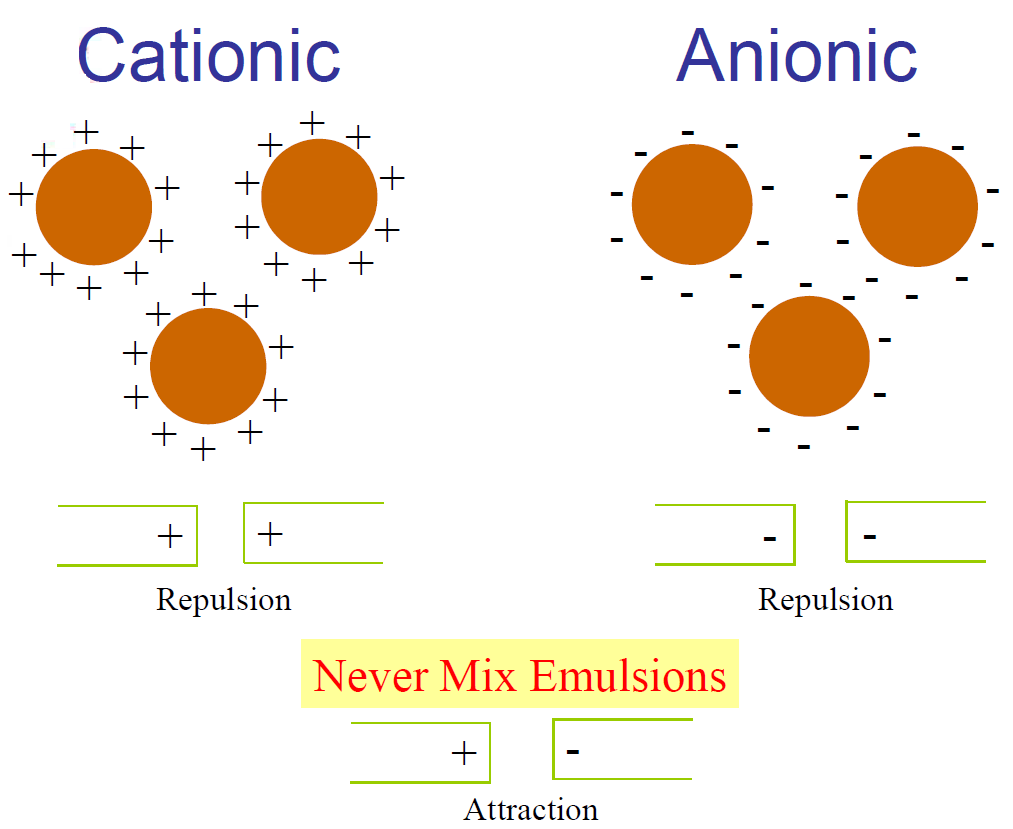

Can I mix them?

Cationic and Anionic emulsions should never be mixed, because the emulsion will become unstable and break nearly immediately causing issues with your equipment. Over-pumping or over-mixing results in shear stress to the asphalt emulsion which can cause the emulsion to break.

Don’t forget to share this article on LinkedIn! Check out Polytrade’s company page.

About the Author

This article was originally published here by Johan Miller and is available in this site with permission from the author. Mr. Miller is an independent road binder specialist and uses his vast knowledge and experience of 27 years to educate professionals in the field. Also, he consults for companies regarding their use of bitumen, emulsions, modified bituminous binders and bitumen rubber. Check out Johan Miller’s LinkedIn for more information.