Let us go back to basics! This article tackles the most commonly asked questions about air-entrained concrete. The top 5 questions on Google are:

- What is air entrainment in concrete?

- Why is air entrainment used in concrete?

- What are the benefits of air entrained concrete?

- How is air entrained concrete made?

- What are the cost savings of including an air entraining agent in concrete?

Below are our (mostly) jargon free answers to the questions above. The answers are self-contained, so feel free to skip to the ones that interest you most.

What is air entrainment in concrete?

Air entrainment is the intentional creation of air voids in the concrete mix. Also, the quality of entrained air and the benefits from air entrainment reply heavily on the quality of its air voids. But what is it? In a nutshell, air voids are microscopic air bubbles within the concrete mix. This special type of air bubble is the secret to excellent air entrainment and all its benefits.

Moreover, there are several factors that influence the quality of the entrained air in concrete. A few examples of factors include the composition of the mixture, consistency of cement, size of aggregate and many others. However, the best predictor of air entrainment quality is the air bubble itself. Curiously, high quality entrained air in concrete is not defined by the quantity of air bubbles. Excellent air entrainment is defined by the diameter and distribution of its air voids.

Why is air entrainment used in concrete?

Air entrainment is the process that creates air voids in concrete. In other words, including microscopic air bubbles in concrete increases the air content. Thus, air entrainment benefits the fresh and hardened state of the mixture.

For example, there are places closer to the equator that have extreme temperature variations daily. In regions like Saudi Arabia and Bolivia, concrete suffers a lot of strain from the climate and altitude. During the day, concrete expands due to extreme heat, while at night it constricts due to chilling temperatures. The repeated cycle of expanding and constricting creates stress in concrete structures. Thus, the strain causes damage in the form of microcracks. Also, if these cracks are not treated properly, permanent damage could invalidate the structure. However, air entrainment enhances concrete properties. In this manner, by increasing the air content in the mix, concrete structures can withstand harsh climate conditions.

Of course, not every city in the world is located in an ecosystem that has a daily high variance in temperature. Buildings, bridges, highways and other structures made of concrete in mild climate regions also greatly benefit from air entrainment. Which leads nicely to our next question…

What are the benefits of air entrained concrete?

In short, air entrainment enhances the properties of concrete in its fresh and hardened state. There are 3 main benefits of entraining air into the concrete mix:

- The fresh state of air entrained concrete has improved workability and pumpability,

- Recently poured concrete is less likely to bleed, and

- Hardened concrete has increased resistance to the freeze-thaw cycle.

Air entrained concrete has improved workability

Since air entrainment increases the air content in concrete, the mixture is easier to work with. In other words, the air bubbles generated act as lubricants between the ingredients that make up concrete. This added lubrification increases the uniformity and pumpability of fresh concrete. In other words, the mixture evens out effectively once poured. Thus, air entrained concrete requires less energy to pump to its intended location and to pour it efficiently.

This benefit is especially useful for large construction sites where the mixing truck cannot physically park next to the pouring site. Instead, a pumping system with special hoses pours the concrete onto the framework.

Another benefit of entraining air into concrete is the possibility of successfully using unconventional materials in the concrete mix. For instance, natural sand can be completely substituted by crushed sand when using the right workability-enhancing additives.

With air entrainment, freshly poured concrete has deceased bleeding of water

In order to explain why air entrained concrete is less likely to bleed, let us explain bleeding.

Due to the composition of concrete, water can separate from the mix. Meanwhile, since water is the least dense of the ingredients, it rises to the top after concrete is poured. So, bleeding occurs when water accumulates at the top of freshly poured concrete. Also, preventing water exudation avoids unwanted problems in hardened concrete.

Consequently, air entrainment is one way to decrease bleeding. Due to the addition of microbubbles in the mixture, the float of well-distributed air bubbles in concrete delays the sedimentation of the solid particles. In this manner, air entrainment retains water where it should be. Thus, air entrained concrete hardens at the slow pace it needs to fully cure.

Air entrained concrete has enhanced resistance to the freeze-thaw cycle in its hardened state

The top benefit of air entrained concrete is its resistance to the damage caused by harsh climates. For example, one common but damaging phenomenon in frosty climates is the freeze-thaw cycle. This event occurs when trapped water in hardened concrete freezes and thaws repeatedly. Since frozen water has 9% more volume than water at room temperature, it creates microcracks in concrete. With time, a microcrack will transform into a visible crack. Consequently, concrete without the proper mix design will continue to deteriorate in colder climates due to the freeze-thaw cycle.

However, air entrained concrete has a higher air content than concrete without entrained air. In this manner, the well-distributed air voids act as expansion chambers for the frozen water. Thus, the air voids within air entrained concrete reduce the probability of microcracks. As a result, air entrainment can enhance concrete properties to withstand the consequences of the freeze-thaw cycle.

How is air entrained concrete made?

The materials that compose air entrained concrete are the same 4 ingredients that manufacture conventional concrete:

- Cement,

- Coarse aggregates,

- Sand (fine aggregates), and

- Water.

However, there is one differentiating factor between air entrained and conventional concrete. Not surprisingly, it is the addition of an air entraining agent into the mix design. In other words, an air entrainer is the ingredient that catalyzes air entrainment within concrete.

Moreover, air entrainment generates air voids in 2 ways. In simple terms, the first way air content in concrete increases is through mechanical agitation. The agitation process of mixing the air entrainer with the other ingredients produces air bubbles. Thus, air entrained concrete is created.

The second way air content in concrete increases is through the release of gases. When all the ingredients interact with each other, chemical reactions occur. Simply put, these chemical reactions release gases that form the air bubbles in air entrained concrete.

In a nutshell, an air entraining agent is a substance that generates innumerous, well-distributed and microscopic air bubbles in concrete. Thus, the air content increases and the concrete mix enjoys the benefits of air entrainment.

What are the cost savings of including an air entraining agent in concrete?

Air entrainment provides better plasticity, uniformity and cohesion characteristics to concrete. In short, air entraining agents make air entrained concrete workable, less likely to bleed and resistant to damage caused by harsh climates.

However, if these benefits alone did not convince you, then let us talk money. Depending on the final application of concrete, the air content can be raised up to 6% with an air entrainer. The resulting mixture has the same volume as one without an air entraining agent. However, all the above-mentioned benefits are included. Simultaneously, there could be a savings of up to 4.5% in costs of cement and other materials. Yes, you read that right. You can save up to 4.5% on your yearly cement consumption by using the right air entrainer.

In short, when the air content is raised within the mixture, less water and materials are needed to keep the same water/cement ratio. For instance, adding air bubbles in the concrete mix reduces the need of water to maintain the same slump. Thus, there should be a reduction in water. (Or else the concrete will not have the correct consistency). Parallelly, reducing water from the mix also reduces cement to maintain the same water/cement ratio.

BONUS: Is air entrained concrete better than “non-entrained” concrete?

In order to answer this question, let us talk about the differentiating factor between these two types of concrete: air.

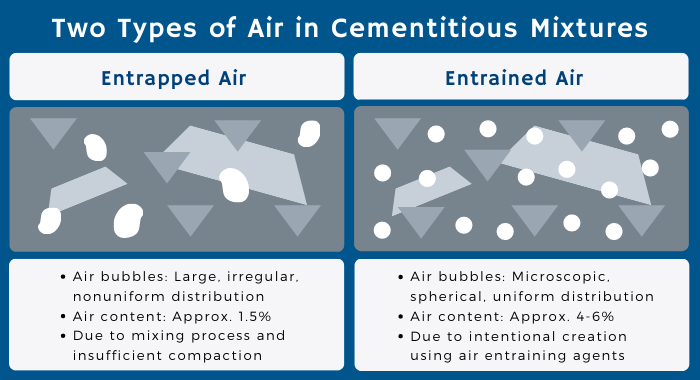

Contrary to popular belief, conventional concrete has air. But the air bubbles are large, irregular and visible to the naked eye. This means that entrapped air only hinders concrete. On the other hand, air entrained concrete has entrained air. Air bubbles generated through air entrainment are microscopic, innumerous, spherical and well-distributed. This means that entrained air is capable of delivering all the benefits of air entrainment. Air entraining agents are catalyzers that convey workability, reduced bleeding and increased resistance from the freeze-thaw cycle to concrete.

Below is an infographic summarizing the characteristics of entrapped and entrained air.

However, the above-mentioned benefits do not come free and there are trade-offs when rising air content. For instance, for every 1% of air that is entrained in concrete, about 5% of compressive strength is reduced. This means that air entrained concrete has less compressive strength than conventional concrete. Thus, just like any tool, air entraining agents should be used wisely to maximize concrete performance and minimize trade-offs.

Nonetheless, air entraining agents are extremely effective and can greatly increase the overall quality of concrete. At the same time, air entrainment boosts the longevity of the structures made with air-entrained concrete. So, there is an argument that air entraining agents should be implemented in all types of construction using concrete and/or mortar. Thus, the catalyzers of air entrainment make structures and buildings safer and stronger. In other words, air-entrained concrete is still concrete, but so much better.

Recommended reading

Enjoyed the topic? Find more with these related blog posts:

1) Top 3 Reasons to use Air Entraining Agents in Concrete

2) What is the freeze-thaw cycle in concrete?

3) Why air entraining agents enable the use of crushed sand in concrete?

4) Natural Materials Links to be Informed in 9 Manufacturing Industries

5) Carbofen is a Vinsol Resin Substitute

Published on JUL-01-2021.